KEF are one of those high powered turbo charged HiFi brands. Partly it’s the name, which in my mind connotes an idea of strength. It sounds like a word for strength – “this product is KEF strong”. It was also probably formed sub consciously when I was a student, as I always wanted to own a pair of KEF speakers which I couldn’t afford. Actually by dictionary definition, KEF means a state of drowsy contentment, which by virtue of what happens when you hear many of their products, is pretty apt. In fact speakers supplying woozy, weak at the knees enjoyment, might be more accurate. So I had a factory tour of KEF’s premises.

The KEF R&D and manufacturing facility at Maidstone, UK, sits within a new apartment block development. Such is the contrast with the new development, the buildings look like something out of the film 28 Days Later. Humans who have survived a virus outbreak, might emerge from here into a population depleted society. Ok I’ve let my imagination go, but the oldness is a cue to the heritage of this brand which has been on this site since 1961. The buildings are owned outright by this speaker firm behemoth.

I was shown around by the immutably friendly and helpful Ron Locke, who has been with the company for a number of years and who I recognised from a HiFi show.

The site is home to the manufacture of the Reference models and best premium Blade 2’s and statement Muon speakers. The Q and R series are made in China, in KEF’s own manufacturing facility there and no doubt for reasons of cost.

When you go into reception you are met with a Blade hanging from the ceiling, which has been cut in half showing all the inner gubbins. All the main current models are shown off in a line to the side. Just off reception is a dedicated show room of all current products, split into product line sections around the room.

You start off looking at the Q series models and then move onto the new R series. The old R series models were 8 years in production, and for anyone who has heard these new models you’d be very welcome of the improvement. I sat listening for some time to a Hegel H190 and a pair of KEF R5’s at a show and I really appreciate the scale and dispersive sound in the mix. In no coincidence due to the KEF Uni-Q technology adopted, which is not still on the same original iteration but has gone through significant development over the years. I won’t bore you as to what this is because most readers will probably know, but this video offers a great explanation ;

As seems a little vacuous to say, being pretty obvious, what KEF learn of higher specced models they develop into cheaper models. So technology used on the Reference series found its way into the new R series. One such area where there is commonality across the entire range is in the use of constrained layer damping. This involves isolating drivers and inner enclosures from the external cabinet by using a damped layer, preventing the cabinet creating its own resonance and affecting sound quality. You can see this clearly by the cut away cabinets on display. I was wondering how long it took to cut these in half – ages I’d imagine! A chap sitting there with an angle grinder dremmel, going around the edges.

Constrained Layer Damping in Reference series speaker

KEF obviously follow furniture trends very closely as clearly you wouldn’t want to retro fit your living room back to a 70s chocolate brown and orange combo. This is reflected in the modern design of the new R series. With the Reference 1’s in luxury gloss rosewood finish, the aim is apparently to get them up to the finish of Steinway Pianos. This is certainly the case with surface quality.

It’s hard to believe the stalwart KEF LS50 speakers have been around for 8 years. They came into production in 2011 to celebrate 50 years of KEF. Relatively recently their concept was taken further by way of the LS50 wireless (active) models, whose aim in part is to really show off the capability of the original passive model. Anyone who knows anything about HiFi and has experienced products knows these £2k speakers to be killers of lots of speaker and amp combos around this same price point.

They utilise a class AB driven tweeter and Class D mid-bass driver. The miniature LSX models are class D all the way through.

The Blade 2 have been made 33% smaller, apparently to suit European consumers with more conservatively sized rooms. An added bonus being the price could be brought down too. The original Blade were great for the US market in this context.

The £140k Muon’s have a big over bearing presence in the show room much like if KEF had placed a museum waxwork of a polar bear there and all the other ‘products’ were sized like marmots or hyenas. It’s a statement product to show off the brand but which is not intended to be a mainstay commercial product. The aluminium case, which is made by a supplier in Coventry, goes through a molten super-forming aluminium process. The huge chunk of aluminium that is the Muon accounts its ostentatious costliness. But it’s certainly impressive – so too the fact that on arrival of the cabinets it takes a week to build in Maidstone.

The Custom Ci series of speakers that KEF make, suit a business model where lots of HiFi dealers now offer custom installs for home cinema and other applications. These are flat panel speakers that can be recessed into walls which KEF are not as well known for.

Everywhere around the premises there lies crossover circuit boards ended with connecting wires to bypass internal crossovers. It’s like an electronics engineers play den with boards marked ‘Blade 2’ or ‘Reference’. Electronic boards lying everywhere like a child would enthusiastically leave meccano on the floor, in pursuit of construction.

I was also invited into KEFs onsite anechoic chamber. The word anechoic literally means ‘free from echo’. The triangular foam sized blocks that most audiophiles know these rooms are constructed of, dissipate sound waves to a point they cannot be reflected from surfaces. Sound being dead and non reflective can then only be measured as coming from speakers. In the middle sits a platform so the speaker can be raised appropriately to test it with the fixed microphone. The floor is a wire grate with foam blocks situated underneath too and pointing upwards. All around these blocks to the side walls there is a gauze material that further stops reflections. Noticeable was the smell of glues used in this very small space.

Its extremely peculiar to hear spoken voices without sound reflection. It messes with your senses and slightly does your head in for the first ten seconds until adapting. I’d imagine this is probably one of the closest ‘messing with the body experiences’ you can do, short of getting in one of those zero gravity aircraft that train astronauts. You just don’t feel you……it’s not your voice….. they aren’t even your arms and legs. How odd!!???

Next door is a room containing moulds and a load of speakers, which is at the opposite scale with a very high ceiling with abundant echo. By measuring speakers in both rooms, the idea is that somewhere in-between a prediction can be made of how your speakers will likely sound at home.

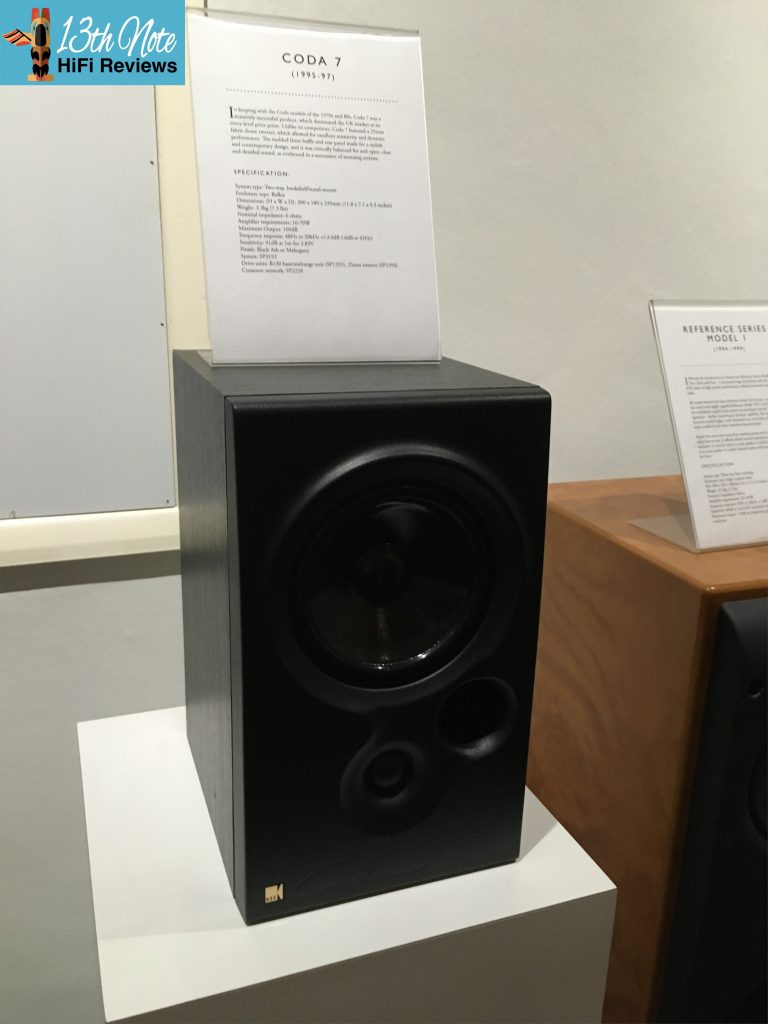

There is also a heritage room showing off all the early and obsolete models. Funny how we actually liked the look of those 90s style speakers with stuck on raised face plates. In a car context they are as appealing now as the wood panels stuck onto Chevy Chase’s car in the film National Lampoon’s Vacation. There is a pair of KEF Coda 7’s from the mid 90s which I remember were very well revered at the time. Also the centre 100C speaker. Off an adjoining room is a pair of the original Blade model in carbon fibre which KEF decided not to sell on account of 46,000 reasons!

Carbon Fibre Blade’s

On site KEF have a home cinema room comprising seven CI3160 THX in-wall speakers and four CI200RR THX in-ceiling speakers connected to an Arcam AVR850 AV amplifier. I was pretty amazed at how this relatively diminutive Arcam could drive all these speaker so well, but such are the virtues of its class G amplification! The room is purpose built as a room within a room and to the exact proportions for best sonics. The level of expansive accuracy was mind blowing and probably the best integrated home cinema set up I’ve heard.

The production facility is smaller than you’d think, but production meets demand using a ‘just in time’ production system. This means parts are supplied ‘just in time’ to be made and there isn’t a need to stockpile hugely. All the staff look very attentive and fastidious at their stations with check sheets everywhere, like how I’d imagine technicians milling around a watch factory, making sure nothing is done wrongly. In the middle of the production process new speakers are compared, across their frequency range, to the reference standard speakers for each model. A frequency sweep is put through the drivers to make sure there are no air leaks from the cabinets, which can apparently be detected by a characteristic chuffing noise.

Much to the dissatisfaction of forum audiophiles who talk about speakers not requiring or using good quality internal cables, the Blade 2 internals use Chord Company Rumour cable.

I’d like to thank Ron and the KEF marketing team for the opportunity of visiting the site and looking into what goes on, as I learnt a lot from the visit and I’m sure my readers would be grateful of the insight too with the photos in this article.

Contact Details

Wesbsite : www.international.kef.com